CNC machining center

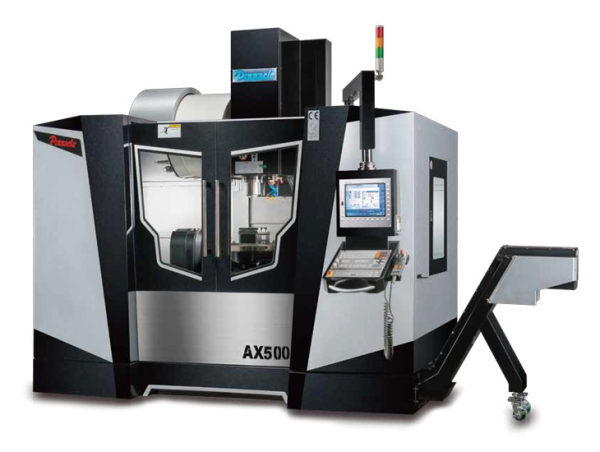

PINNACLE AX500 5-axis machining center (with rotary-tilting table)

Priced individually

No rating

12 months of warranty

Contact with a trader:

Tomasz Kierzkowski

E-mail: tomasz.kierzkowski@eurometal.com.pl

Telefon: 603505252

Tomasz Kierzkowski

E-mail: tomasz.kierzkowski@eurometal.com.pl

Telefon: 603505252

The PINNACLE AX500 machining center is a 5-axis machine with a rotary-tilting table. The machine frame is made of ribbed Meehanite cast iron. The headstock is equipped with a pneumatic counterbalance, which significantly minimizes vibration of the column and headstock itself during dynamic changes in direction. 5-axis machining allows for the production of complex shapes in a single setup, increasing accuracy and reducing machining time.

The PINNACLE AX450 machining center is a 5-axis machine with a rotary-tilting table. The machine frame is constructed of ribbed Meehanite cast iron. The headstock is equipped with a pneumatic counterbalance, which significantly minimizes vibration of the column and headstock itself during dynamic changes in direction. 5-axis machining allows for the production of complex shapes in a single setup, increasing accuracy and reducing machining time.

Linear roller guides and optional linear scales enable high dynamic axis movement and high positioning accuracy.

To enhance machining accuracy and smooth motion, the machine headstock and ball screws are oil-cooled.

The AX series machines are available with three worktable sizes: ø320, ø400, and ø500mm. The machining centers can be equipped with Heidenhain, Sinumerik, or Fagor controls. If the workpiece does not require 5-axis interpolation, it is possible to order a 4+1 machine (4 interpolated axes + 1 indexed), which will significantly reduce the purchase costs.

AX series – 5-axis machining centers with a tilting rotary table

- ISO40 spindle taper

- Integrated tilting rotary table – A and C axes

- Table tilt – A axis range: -110° to +110°

- Table rotation – C axis operating a full 360°

- Worktable diameter: Ф500mm

- Optional direct-drive spindles: 10,000 rpm or 12,000 rpm

- Optional electrospindle: 15,000 rpm

Main features of the AX series

- The main structural components are made of high-quality Meehanite (FC-30) iron castings.

- Precision "P" class linear guides use rollers instead of traditional balls, significantly increasing their stiffness and load capacity.

- Travel speeds of 30/30/24 m/min in the X/Y/Z axes.

- The spindle features high-precision P4 class bearings. The spindle provides a wide range of machining operations and high speeds.

- The spindle's oil cooling circuit prevents thermal expansion and ensures optimal machining conditions.

- Table tilt – A axis – ranges from -110° to +110°.

- Table rotation – C axis operates a full 360°.

- Worktable diameter: 500mm.

- Optional HEIDENHAIN linear scales – double-loop feedback – ensure maximum feed precision.

- Machines designed for use in the aviation, aerospace, and medical industries, for all workpieces requiring maximum precision.

- Worktable tilt and rotation are achieved by servomotors, through worm gears with backlash compensation. Positioning accuracy for the A/C axes is 15"/10", respectively, and positioning repeatability is 10"/5".

Standard equipment:

- Spindle oil purge

- Workpiece air purge

- Telescopic guide covers

- Enclosed workspace

- Automatic central lubrication system

- X/Y/Z linear scales

- A/C axis encoder

- Work lighting

- Signal mast

- Cooling system

- Coolant gun

- Compressed air gun

- HR410 handwheel

- USB/RJ45 interface

- Heidenhain TNC640 control

- DCM, kinematic function

- Oil-cooled spindle

- Tool box

- Screw chip conveyor

- 20-piece drum tool magazine

- Leveling screws and shims

- English user manual

- CE declaration of conformity

Optional equipment (additional charge):

- Through-spindle cooling

- Tool probe

- Workpiece probe

| Technical data | Unit | Value |

|---|---|---|

| Table surface (length) | [mm] | 500 |

| Table surface (width) | [mm] | 500 |

| X axis travel | [mm] | 760 |

| Y axis travel | [mm] | 610 |

| Z axis travel | [mm] | 560 |

| Table load | [kg] | 350 |

| Workpiece size | [mm] | 600x305 |

| The diameter of the hole in the worktable | [mm] | 50 |

| T-slots (W x Pitch mm x °) | [-] | 12x90° |

| Distance between the spindle and the table | [mm] | 35~595 |

| A axis rotation | [°] | 220 (±110) |

| C axis rotation | [°] | 360 |

| Spindle taper | [-] | ISO40 |

| Spindle speed | [rpm/min] | 0 - 10000 |

| Spindle speed (direct drive) | [rpm/min] | 0 - 12000 |

| Spindle speed (electrospindle) | [rpm/min] | 15000 - 20000 |

| FANUC servo motor (continuous / 30min KW) | [-] | 9/12 |

| Rapid feed (X / Y / Z) | [m/min] | 30/30/24 |

| Working feed (X / Y / Z) | [m/min] | 10/10/10 |

| Working feed (A / C) | [rpm/min] | 30/90 |

| Tool magazine type | [-] | łańcuchowy |

| Tool magazine capacity | [pcs] | 24/30/40 |

| Tool diameter | [mm] | 90/76 |

| Tool length | [mm] | 250 |

| Tool weight | [kg] | 8 |

| Electrical connection | [kVA] | 40 |

| Coolant tank capacity | [l] | 300 |

| Compressed air pressure | [MPa] | 6 |

| Dimensions (LxWxH) | [mm] | 3150x2230x2560 |

| Weight | [kg] | 7100 |

Media

16.12.2021

Test stołu obrotowego 2osiowego Pinnacle

Recommended

CNC machining center

Priced individually

No rating

CNC machining center

Priced individually

No rating

CNC machining center

Priced individually

No rating

Newsletter

Sign up for our newsletter.

We have sent a message with a verification link to the e-mail address provided.