CNC machining center

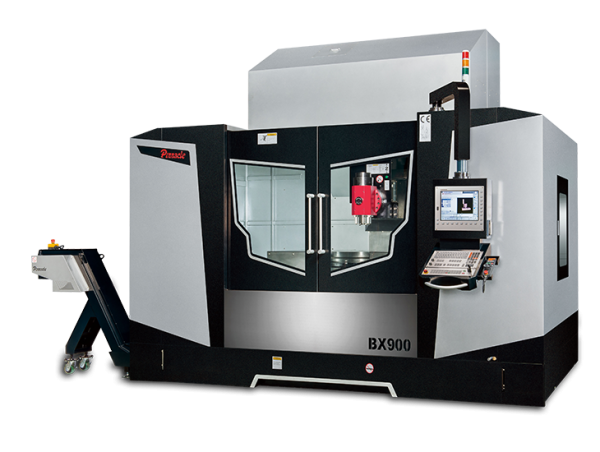

PINNACLE BX900DD 5-axis machining center (with rotary head + rotary table)

Priced individually

No rating

12 months of warranty

Contact with a trader:

Michał Bartoszuk

E-mail: michal.bartoszuk@eurometal.com.pl

Telefon: 603505252

Michał Bartoszuk

E-mail: michal.bartoszuk@eurometal.com.pl

Telefon: 603505252

The PINNACLE BX900DD 5-axis machining center (with rotary head + rotary table) offers the latest and most precise 5-axis technology on the market. It simplifies the setup and production of complex and multi-sided parts with precision, accuracy, and time savings. Optimized 5-axis concepts meet all requirements and dominate all industries worldwide.

PINNACLE BX900DD 5-AXIS MACHINING CENTER (with rotary head + rotary table)

Pinnacle's BX series machines offer the latest and most precise 5-axis technology on the market. They simplify the setup and production of complex and multi-sided parts with precision, accuracy, and time savings. Optimized 5-axis concepts meet all requirements and dominate all industries worldwide. Designed by Taiwanese engineers, the BX series features a high-rigidity structure that provides the widest working range. High-quality Meehanite cast iron, stress-relieved and with a hardness exceeding HB190, ensures years of distortion-free operation.

functions:

- Szybkie i dokładne ruchy przewodnie

- Wysokiej jakości powierzchnia po obróbce

- Najkrótszy czas obróbki, dla maszyn tego typu

B-AXIS ROTARY MILLING HEAD

UNIQUE B-AXIS DESIGN

The BX700DD's B-axis transmission mechanism has been upgraded from a dual worm gear/shaft design to a direct drive. In addition to smooth and powerful torque, the direct drive system boasts higher rotational speed, high servo response, zero backlash, and exceptional dynamic accuracy for optimal workpiece surface finish. An external cooling system effectively minimizes structural thermal distortion and accuracy deviation, and output torque is maintained by maintaining a constant low and stable temperature.

The rear end of the B-axis shaft is equipped with an angular position encoder to enhance B-axis positioning accuracy. The use of a direct-drive motor on the B and C axes increases the machine's overall accuracy and machining efficiency.

The Pinnacle BX is the most cost-effective production investment in 5-axis simultaneous machining centers. It delivers positive and immediate results, improving machining accuracy and reducing machining time.

The BX700/BX500 is a high-speed, high-accuracy 5-axis machining center with HEIDENHAIN TNC640 simultaneous control. Equipped with a built-in 15,000 rpm spindle, a ±120° B-axis swivel head, and a Ø630 mm C-axis rotary table (built-in DD C-axis), it optimizes machining space and enables the finishing of complex workpieces in a single setup, reducing cycle times.

PNEUMATIC BALANCING SYSTEM

The Z axis is pneumatically balanced using high-response pneumatic actuators. An additional air reservoir is installed to increase balancing performance, ensuring fast and stable Z-axis movement, ensuring high surface quality.

SPINDLE COOLING SYSTEM

The spindle oil cooler maintains a constant spindle temperature and ensures long service life. It also ensures high machining efficiency and high accuracy.

ROLLER LINEAR GUIDE

The X/Y/Z axes feature roller guides for optimal stiffness and speed. Six rollers on the X/Z axes minimize damping.

RIGID MACHINE BASE AND SADDLE

Drive motors directly coupled to pre-tensioned and oversized ball screws to ensure cutting quality.

HOLLOW BALL SCREW WITH COOLING SYSTEM

Oil cooling through ball screws on X, Y, Z axes minimizes thermal distortion and backlash while ensuring smooth movement during rapid feed.

CNC CONTROLLER SYSTEM

The BX series features the fast and precise HEIDENHAIN TNC640 5-axis machining center, which is simultaneously controlled. It comes standard with a built-in 15,000 rpm spindle.

AIRCRAFT FUNCTION

The PLANE function makes it easy to define an inclined work plane, making everything faster.

TILTING THE WORK COAT

Possibility of tilting the work plane. With Cycle 19 with rotary heads or tilting tables. The operation is normally programmed in the machining plane, e.g., in the X/Y axis. The machine starts the program in a plane that has been tilted by one or more rotary axes relative to the main plane.

DCM (DYNAMIC COLLISION MONITORING)

DCM allows collision checking in test run mode before actual part machining. This helps avoid machine downtime. Simulation helps maintain safety processes.

TCPM (TOOL CENTER POINT MANAGEMENT) FUNCTION

In five-axis operations, the TCPM function reliably guides the tool along the contour and ensures that the workpiece surface is not damaged. It also maintains the tool tip position during tilted axis positioning.

Using the TCPM function, the iTNC 530 automatically corrects the tool path based on the machine geometry and tool length, as well as compensating the tool radius in three dimensions.

CHIP WASHING SYSTEM

The chip flushing system is designed to remove chips inside the housing, preventing chip buildup and possible damage to linear guides and ball screws.

COOLING THROUGH SPINDLE (OPTIONAL)

A 20 bar high pressure pump and auxiliary tank give the CTS system the highest chip removal efficiency.

CHIP CONVEYOR (OPTIONAL)

A hinged or scraper type chip conveyor at the front of the machine (with left or right head capability) removes chips from the machine.

KINEMATICS OPT. (OPTIONAL)

Kinematice Opt. is a key component that helps meet these demanding requirements: Once a HEIDENHAIN touch probe is inserted, the 3D touch probe cycle measures the machine's rotary axes fully automatically. The measurement results are the same regardless of whether the axis is a rotary table, a swivel table, or a swivel head.

B-AXIS ROTARY MILLING HEAD

BALL ROD DIAGNOSTICS

Standard equipment:

- Spindle air blast

- Coolant system

- Full splash guard

- Automatic lubrication system

- Work light

- Operation status indicator

- Rigid tapping

- Z-axis pneumatic balance system

- Air gun/water gun

- MPG handwheel

- Spindle oil cooler

- B-axis rotary encoder

- C-axis rotary encoder

- Hollow ball screws with coolant system

- RS-232 interface

| Technical data | Unit | Value |

|---|---|---|

| Table surface (length) | [mm] | 1700 |

| Table surface (width) | [mm] | 850 |

| X axis travel | [mm] | 1500 |

| Y axis travel | [mm] | 900 |

| Z axis travel | [mm] | 1000 |

| Table load | [kg] | 1200 |

| The diameter of the hole in the worktable | [mm] | 70 |

| T-slots (W x Pitch mm x °) | [-] | 18x150x5 |

| Spindle taper | [-] | BT40 |

| Spindle speed | [rpm/min] | 0 - 15000 |

| Electric spindle power (continuous / 30 min KW) | [-] | 15 / 19.4 |

| Distance from the spindle axis to the column surface | [mm] | 950 |

| The inclination of the electro-spindle head | [°] | ± 120 |

| Head rotation speed | [rpm/min] | 50 |

| Rapid feed (X / Y / Z) | [m/min] | 20/20/16 |

| Working feed (X / Y / Z) | [m/min] | 10000 |

| Tool magazine type | [-] | bębnowy |

| Tool magazine capacity | [pcs] | 30(60) |

| Tool diameter | [mm] | 75 |

| Tool length | [mm] | 250 |

| Tool weight | [kg] | 8 |

| Electrical connection | [kVA] | 40 |

| Coolant tank capacity | [l] | 300 |

| Rotary table type | [-] | wbudowany w stół główny |

| Rotary table diameter | [mm] | 800 |

| The diameter of the hole in the turntable | [mm] | 60 |

| Rotation speed of the turntable | [rpm/min] | 50 |

| Load on turntable | [kg] | 1200 |

| Distance between the spindle and the table (head vertical) | [mm] | 115 - 1115 |

| Spindle distance from the table (head horizontally) | [mm] | 255 - 1355 |

| X / Y / Z axis positioning accuracy | [mm] | 0.005 |

| A / C axis positioning accuracy | [mm] | 0.003 |

| Compressed air pressure | [MPa] | 6 |

| Dimensions (LxWxH) | [mm] | 3450x4450x4340 |

| Weight | [kg] | 15000 |

Media

16.12.2021

5 osiowe centrum obróbcze cnc Pinnacle seria BX (cz. 1)

16.12.2021

5 osiowe centrum obróbcze cnc Pinnacle seria BX (cz. 2)

16.12.2021

5 osiowe centrum obróbcze cnc Pinnacle seria BX (cz. 3)

16.12.2021

5 osiowe centrum obróbcze cnc Pinnacle seria BX (cz. 4)

16.12.2021

5 osiowe centrum obróbcze cnc Pinnacle seria BX (cz. 5)

16.12.2021

5 osiowe centrum obróbcze cnc Pinnacle seria BX (cz. 6)

16.12.2021

5 osiowe centrum obróbcze cnc Pinnacle seria BX (cz. 7)

16.12.2021

5 osiowe centrum obróbcze cnc Pinnacle seria BX (cz. 8)

Recommended

CNC machining center

Priced individually

No rating

CNC machining center

Priced individually

No rating

CNC machining center

470 787,42 zł

No rating

Newsletter

Sign up for our newsletter.

We have sent a message with a verification link to the e-mail address provided.