Machine categories

Band saws

IMET X-SMART3 automatic column band saw

148 950,00 zł net

No rating

12 months of warranty

Contact with a trader:

Michał Bartoszuk

E-mail: michal.bartoszuk@eurometal.com.pl

Telefon: 603505252

Michał Bartoszuk

E-mail: michal.bartoszuk@eurometal.com.pl

Telefon: 603505252

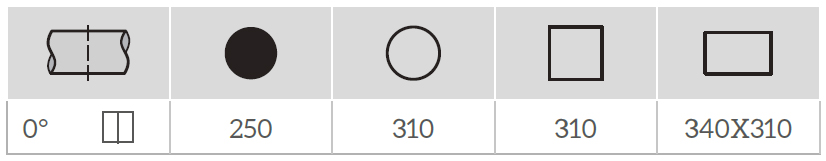

XSMART3 is an automatic double column bandsaws for straight cuts and totally managed by CNC with 7" touch screen display, easy and intuitive interface. Fully protectedy by carters to provide maximum security to the user, it's an easy to use professional tools that can be installed in every environment and mechanic workshop.

Quantity

Add to cart

7" touch screen display

XSMART3 has an easy, intuitve and user-friendly interface with a 7" touch screen display that allows to have full control on all the machine parameters and all the operative settings. Using CNC system, the user will have the possibility to optimize his user-experience and workflow with just few clicks. These features, combined with the solid structure, make XSMART3 the perfect working tool for industry application.

Sawframe

XSMART3 sawframe has an elctrowelded rigid structure on double column which helps reduce vibrations and binding during descent. Like many IMET bandsaws, its blade is canted (30°) to reduce the band strain and have better and constant sawframe descent while cutting with optimized performances on every material, profiles or solid.

Feeder with roller table

XSMART feeder has a single stroke of 500mm with integrated roller table for material support. The feeder moves with a recyrculatig screw and electric motor with inverter, portal structure that ease material movement and loading.

Full stroke vice

The machines uses an hydraulic full stroke vice to lock the material wtih jaws place both before and after the cutting line.

Blade cleaning

All the semiautomatic and automatic IMET bandsaws are equipped with a mechanical cleaning brush with nyloni fibers that helps to remove residuals and remainings while cutting.

Full stroke vice

The machines uses an hydraulic full stroke vice to lock the material wtih jaws place both before and after the cutting line.

Blade cleaning

All the semiautomatic and automatic IMET bandsaws are equipped with a mechanical cleaning brush with nyloni fibers that helps to remove residuals and remainings while cutting.

Washing gun

Premium Line automatic bandsaws and semiautomatic and automatic Maxi Line bandsaws are standardly equipped with a washing gun dedicated to keep clean the working area and remove any residuals and remainings, allowinga to keep the highest efficiency of the machine.

Blade guide

Hard metal blade guides with bearings to have an optimal blade allignment during the cutting process. The mobile blade guide is kept automatically next the cutting point.

Chips conveyor

Standard on XSMART3 there's a chip conveyor that helps remove any material remaining while the machine works.

RBonfiglioli motor-reducer

XSMART3 uses Bonfiglioli motor-reducer to have the highest reliability and functionality.

Standard equipment:

- CNC control with the ability to program different lengths and quantities on the same material

- feeding vices with a bridge structure and a roller feeder

- material is fed via an electric motor and a ball screw

- double vice for mounting the cut profile before and after the blade

- the inclination of the tension wheels at an angle of 30 degrees allows to extend the life of the belts

- two-column saw frame with sliding on linear guides

- moving the blade head on linear guides and recirculating ball screws, with

- automatic quick access to the workpiece

- sensor for automatic detection of the starting cutting point

- standard vice clamp adjustment

- standard cutting feed adjustment

- mobile control panel

- LED lighting to illuminate the work area

- completely protected with covers with easy access for service

- chip conveyor

- final waste 10 mm

- washing gun

- double clamp bridge feeder design with roller support

- powered brush

Industry 4.0 Ready - SAWFACTORY

IMET automatic machines can be connected to the company network and be used remotely thanks SAWFACTORY and modem. SAWFACTORY is a dedicated software which allows to manage the cutting process from the office desk by setting cutting programs and monitoring the workflow thanks to the dedicated web app. The software also allows to also receive assistance by our technicians remotely.

Minimal lubrification system

It is possible to require, for all Imet machines, the minimal lubrication system, it avoids the dispersion of refrigerant liquid typical in the use of emulsifiable oil, the life of the blade is not in any way o affected. Minimal lubrification system for XSMART3 has a 1.3 l tank capacity.

Pressure regulation

It's possible to add two supplementary pressure reducers to regulate both machine's vices (feeder vice and the fix vice) in order to cut even the shorter length.

Deluxe Kit

Deluxe Kit is an available optional dedicated to increase the user-experience and optimize the professional user workflow: it includes the blade deviation control system, the smart start system to set trim cut quote and sawframe descent speed view on machine display.

Bundle cutting device

It's possibile to require the hydraulic device for bundle cutting which takes cutting capacity at 340x250mm maximum and 130x10mm minimum while bundle cutting scrap-end is 280mm.

How to use bundle device

It's possibile to use the bandsaw also for the cut of a single piece (minimum diameter 110mm) even with the bundle device already assembled: the user must disconnect the tubes that connect the two bundle piston (thanks to the fast graftings) and move the vertical pistons and bundle group laterally next to the vice. Also the horizontal plate, located on the fixed vice, must be removed (by two screws); with Deluxe Kit, capacity: 60mm.

| Technical data | Unit | Value |

|---|---|---|

| The width of the cutting band | [mm] | 34 |

| Vise opening width | [mm] | 340 |

| The dimensions of the cutting band | [mm] | 3730 |

| Cutting band speed | [m/min] | 15-100 |

| Cutting band motor power | [kW] | 3 |

| Working height | [mm] | 920 |

| Final waste | [mm] | 90 |

| Length of a single pass | [mm] | 500 |

| Coolant tank capacity | [l] | 50 |

| Hydraulic reservoir capacity | [l] | 20 |

| Dimensions | [mm] | 1950x1755x1965 |

| Weight | [kg] | 1650 |

Recommended

Newsletter

Sign up for our newsletter.

We have sent a message with a verification link to the e-mail address provided.