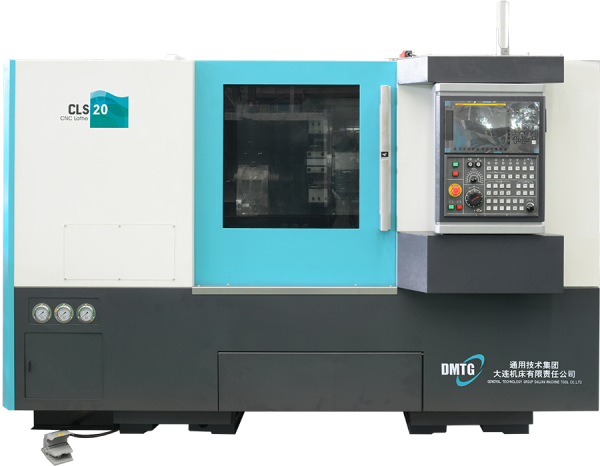

CNC Lathes

DMTG CLS-20 CNC LATHE

Priced individually

No rating

12 months of warranty

Contact with a trader:

Michał Bartoszuk

E-mail: michal.bartoszuk@eurometal.com.pl

Telefon: 603505252

Michał Bartoszuk

E-mail: michal.bartoszuk@eurometal.com.pl

Telefon: 603505252

The DMTG CLS-20 CNC lathe is a two-axis, coordinated semi-closed loop CNC lathe. The main body of the machine is fully cast, with the bed guide system inclined at an angle of 45 degrees, which ensures high rigidity. The control system uses FANUC 0i-TF, GSK and other systems, as well as AC servo drives. It is able to perform various turning processes on axial elements in the range of φ260mm and disc-type elements in the range of φ300mm.

The DMTG CLS-20 CNC lathe is a two-axis, coordinated semi-closed loop CNC lathe. The main body of the machine is fully cast, with the bed guide system inclined at an angle of 45 degrees, which ensures high rigidity. The control system uses FANUC 0i-TF, GSK and other systems, as well as AC servo drives. It is able to perform various turning processes on axial elements in the range of φ260mm and disc-type elements in the range of φ300mm.

- Equipped with systems such as Fanuc Oi-TF, GSK, with USB ports and a 10.4-inch color LCD display

- High-strength cast iron bed

- Parallel belt transmission

- Wide linear guide, X - 35 mm \ 1.378", Z - 35 mm \ 1.378"

- Servo motor connected directly to the lead screw, X - φ28 mm \ φ1.102", Z - φ36 mm \ φ1.417"

- Higher rapid traverse speed, X - 20 m/min \ 787 ipm, Z - 24 m/min \ 945 ipm

- Machining with high and low guide rail beds avoids secondary positioning and clamping, making the machining process simpler, highly precise and more stable

- Rear chip discharge, side chip discharge

Standard equipment:

- 8-position hydraulic tool tower

- nsk spindle bearings and x/z axis bearings

- x/z ball screws and linear guides

- Hydraulic chuck without through hole

- Hydraulic tailstock

- Chip tub

- Automatic lubrication system

- Standard tool kit

- CE certificate

- User manual in English

Optional equipment (additionally paid):

- 12-position hydraulic tool tower

- x/z thk ball screws and thk linear guide

- Through-hole hydraulic chuck

- Device for pre-setting tools

- Air conditioner

- Oil mist separator

- Bar feeder

- Chain chip conveyor

- Automatic doors

| Technical data | Unit | Value |

|---|---|---|

| Turning diameter over bed | [mm] | 500 |

| Rotation speed | [rpm/min] | 4500 |

| Spindle tip | [-] | A2-6 / Opcja: A2-8 |

| Spindle flight | [mm] | F62 (F87) |

| X / Z accelerated feed | [m/min] | 165/500 |

| Extend the tailstock quill | [mm] | 460 |

| Tailstock sleeve diameter | [mm] | 80 |

| Tailstock taper | [-] | MT4 |

| Main spindle motor | [kW] | 11/15 |

| Longitudinal feed | [mm/rpm] | 0 - 5000 |

| Max. turning diameter (shaft) | [mm] | 260 |

| Max. turning diameter (disc) | [mm] | 300 |

| Max. turn length | [mm] | 450 (350) |

| Guide type | [-] | Prowadnica liniowa |

| Handle size | [*] | 8 (10) |

| Max. rod capacity (equipped with through-hole hydraulic chuck) | [mm] | F51 (F74) |

| Tower type and number of tools | [-] | Hydrauliczna wieża 8-pozycyjna (opcja: wieża 12-pozycyjna) |

| Tool shank size | [mm] | 25x25 |

| Indexing time (adjacent/farthest) | [s] | 0,45/1,2 (0,45/1,45 12-pozycyjna wieża) |

| Tailstock step | [mm] | 130 |

| Positioning accuracy of the X/Z axis (C, Y) | [mm] | 0,008/0,008 |

| Repeatability accuracy of the X/Z axis (C, Y) | [mm] | 0,004/0,004 |

| External dimensions L x W x H | [mm] | 2900×2870×2000 (Tylny przenośnik wiórów) 3900×1740×2000 (Boczny przenośnik wiórów) |

| Net weight | [kg] | 4000 |

Recommended

Newsletter

Sign up for our newsletter.

We have sent a message with a verification link to the e-mail address provided.