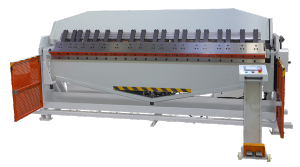

Hydraulic CNC bending machine EUROMET ZHS 2504 (4x2540)

Krzysztof Penkowski

E-mail: krzysztof.penkowski@eurometal.com.pl

Telefon: 603 400 333

The hydraulic CNC bending machine EUROMET ZHS 2504 (4x2540) is designed for the production of bent sections made by successive bending of sheet metal. After using special tools, it is possible to make various boxes, bend sheet metal edges, etc. The machine has the ability to electronically set the angle. The device has a portable control panel and a divided upper knife. The machine's design uses a hydraulic unit - this ensures high precision of work and reliability of operation.

- High precision across the entire width of the material

- Strong rigid construction

- Hydraulic drive of gears and rack for better control and higher bending accuracy compared to standard hydraulic system

- Easy adjustment of material thickness / simple thickness setting

- Adjustable hydraulic pressure matched to the material thickness, which prevents surface damage

- Fast and precise bending of G panels with high accuracy

- Protective barrier with photocell compliant with CE standard

- Min. reverse bending 20mm

- Max. box height 100mm

- Electronic setting of bending angle and backgauge position

|

Specification |

Model |

|||||

|

ZHS2004 |

ZHS2504 |

ZHS3104 |

||||

|

Max. bending length |

(mm) |

2035 |

2540 |

3100 |

||

|

Max. bending thickness |

(mm) |

4,0 |

4,0 |

4,0 |

||

|

Max. lifting height of the upper beam |

(mm) |

200 |

200 |

200 |

||

|

Bending angle |

0°~150° |

0°~150° |

0°~150° |

|||

|

Max. bumper travel rear |

(mm) |

800 |

800 |

800 |

||

|

Dimensions |

L |

(mm) |

|

3000 |

3850 |

4450 |

|

W |

(mm) |

|

2100 |

2100 |

2100 |

|

|

H |

(mm) |

|

1750 |

1860 |

1950 |

|

|

Weight |

(Kg) |

2500 |

3900 |

5000 |

||

|

Main motor power: |

(KW) |

5,5 |

7,5 |

7,5 |

||

- Quick change of the upper tool holder

- Manual gap adjustment

- Portable control panel with foot switch

- 2-axis CNC control system with a 10-inch touch screen

- 800mm CNC backgauge driven by a servo motor

- Hydraulic pressure and clamping pressure regulated by the control system

- Electronic setting of the bending angle and backgauge

- CE declaration of conformity

- User manual in English

- Reargauge extended to 1000 / 1250 mm

- Non-standard blade shape

| Technical data | Unit | Value |

|---|---|---|

| Knife length | [mm] | 2540 |

| Maks. grubość blachy (stal czarna) | [mm] | 4 |

| Sheet thickness (carbon steel) | [mm] | 2 |

| Bending angle | [°] | 150 |

| Opening | [mm] | 200 |

| Rear bumper length max | [mm] | 800 |

| Main engine | [kW] | 7,5 |

| Dimensions | [mm] | 3850 x 2100 x 1860 |

| Weight | [kg] | 3900 |

Recommended

Newsletter